Pipeline systems are the backbone of the critical infrastructure of any country, they are increasingly important as a means of transport of large volumes of oil and gas, or other hazardous substances over long distances. Accidents related to such systems can have severe consequences to the environment and people living in the area, and can involve years of legal proceedings against operating companies and those responsible.

Digital twins, combined with infrasound sensors, offer a groundbreaking approach to monitoring pipeline integrity and mitigating potential risks.

Infrasound, with its low-frequency sound waves, can detect even the slightest anomalies in pipeline infrastructure, providing early warnings for potential leaks, cracks, or structural weaknesses. It has the capacity to detect sound waves that are below the threshold of human hearing, typically below 20 Hz. These sensors are highly sensitive and can pick up even the slightest vibrations or acoustic signals.

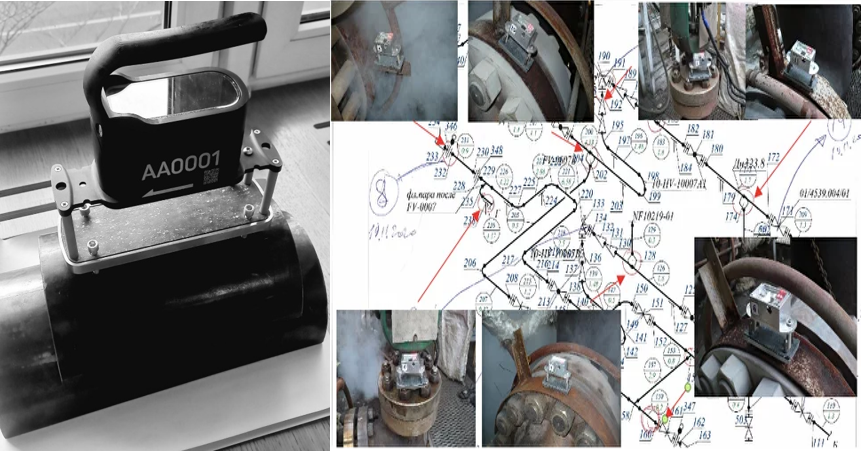

When it comes to detecting vibrations on a pipeline, infrasound sensors are strategically placed along the pipeline route depending on its design and structure as the red edges shows in the schema on the top. These sensors are capable of capturing the unique acoustic signatures generated by various events, such as leaks, cracks, or structural weaknesses.

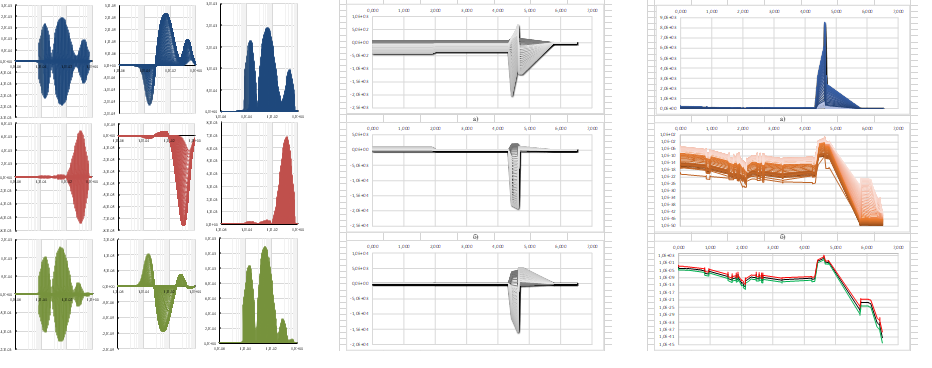

When a vibration or disturbance occurs on the pipeline, it generates sound waves that propagate through the surrounding medium, as the picture shows below. Infrasound sensors are designed to capture these sound waves, even at long distances.

Infrasound, with its low-frequency sound waves, can detect even the slightest anomalies in pipeline infrastructure, providing early warnings for potential leaks, cracks, or structural weaknesses. It has the capacity to detect sound waves that are below the threshold of human hearing, typically below 20 Hz. These sensors are highly sensitive and can pick up even the slightest vibrations or acoustic signals.

When it comes to detecting vibrations on a pipeline, infrasound sensors are strategically placed along the pipeline route depending on its design and structure as the red edges shows in the schema on the top. These sensors are capable of capturing the unique acoustic signatures generated by various events, such as leaks, cracks, or structural weaknesses.

When a vibration or disturbance occurs on the pipeline, it generates sound waves that propagate through the surrounding medium, as the picture shows below. Infrasound sensors are designed to capture these sound waves, even at long distances.

The captured infrasound data is then processed and analyzed using our digital twin model based on mathematics, physics and digital signal processing. By comparing the collected data with baseline measurements and predefined patterns, we can identify abnormal vibrations or acoustic signatures that indicate potential issues with the pipeline's integrity.

Join the revolution in pipeline safety and explore the transformative potential of digital twin technology! Let's collaborate to build a safer future for our pipeline infrastructure: https://the-digital-twin.com/infrastructure